When you pick up a prescription, you rarely think about who made the pill or how much it cost to produce. But behind every generic drug and every brand-name drug is a very different story - especially when it comes to labor. The truth is, generic drug production doesn’t just cost less because it’s copied. It costs less because the way it’s made is fundamentally different - and labor is at the heart of that difference.

Why Generic Drugs Are Cheaper - It’s Not Just the Active Ingredient

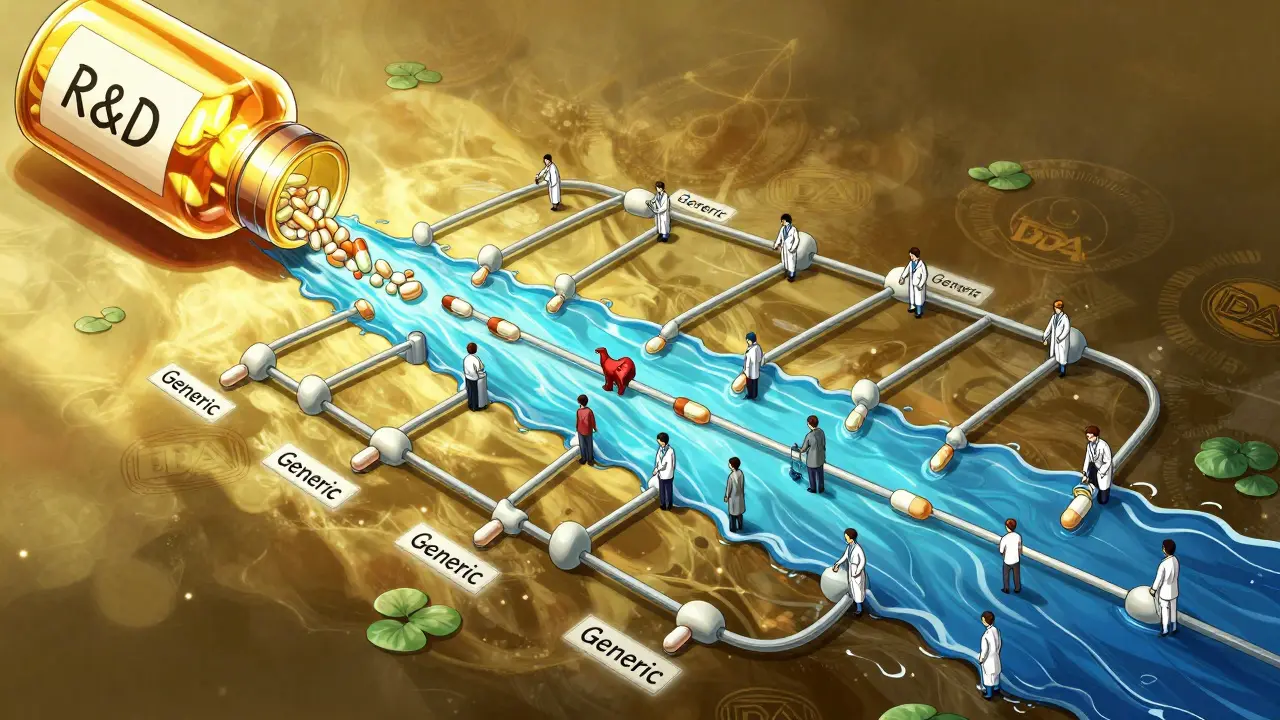

Many people assume generic drugs are cheaper because they use the same active ingredients as brand-name drugs. That’s true - but it’s only half the story. The real savings come from how those ingredients are turned into pills. Brand-name drugs are developed from scratch. That means years of research, clinical trials, regulatory filings, and patent protection. All of that costs billions. Generic manufacturers don’t do any of that. They skip the R&D entirely. But that doesn’t mean their work is easy. In fact, generic manufacturers face a different kind of pressure: volume. Nine out of every ten prescriptions filled in the U.S. are for generics. That means factories producing generics churn out millions, sometimes billions, of pills a year. And when you make that much, you can spread your labor costs across a massive number of units. One study found that for every time a generic drug’s production volume doubles, the cost per unit drops by 27%. That’s far more efficient than what brand-name makers see. It’s not magic. It’s math.Labor Costs: The Hidden Split Between Generic and Brand

Labor isn’t just about how many people are on the floor. It’s about what they’re doing, how much they’re paid, and how much time they spend on each task. For brand-name drugs, labor makes up 30% to 40% of total production costs during early production. Why? Because every step is new. Every batch is scrutinized. Every process is being refined. You need highly trained scientists, engineers, and quality specialists working side by side - often for years - just to get the drug approved and stable enough to mass-produce. Generic manufacturers? Their labor costs are more like 15% to 25% of total production. That’s not because they pay workers less - though that’s part of it - but because their processes are standardized. They’re not inventing anything. They’re repeating a proven formula. A single line can produce hundreds of thousands of tablets an hour. The workers aren’t designing the process. They’re monitoring it. And because the process is so well-known, they need fewer people per unit of output. But here’s the catch: quality control still eats up more than 20% of a generic drug’s total cost. That’s labor-intensive. Every batch of raw materials must be tested. Every tablet must be checked for weight, dissolution, and purity. Documentation for each batch has to be perfect. One mistake, and the whole lot gets thrown out. That’s not cheap. For a medium-sized generic maker, just keeping up with FDA compliance costs about $184,000 a year in labor and systems alone. Add in the cost of submitting new drug applications, and you’re looking at over $2 million in annual expenses just to stay legal.

Where the Work Happens - And Who Gets Paid

You might think all drug manufacturing happens in the U.S. It doesn’t. About 80% of the active ingredients in U.S. generic drugs come from India and China. And the labor cost difference there is dramatic. Producing the same API (active pharmaceutical ingredient) in India costs about 42% less than doing it in the U.S. That’s not because Indian workers are more skilled. It’s because wages are lower, regulations are less strict, and factories operate at massive scale. This isn’t just about efficiency. It’s about structure. The U.S. Department of Health and Human Services found that these low costs aren’t the result of better technology or smarter management. They’re the result of subsidies, weaker labor protections, and environmental standards that don’t match U.S. levels. So when you buy a $4 generic pill, part of that low price comes from labor practices you wouldn’t accept at home. Still, even with global sourcing, U.S.-based generic manufacturers are under pressure. As prices keep falling - thanks to competition among dozens of generic makers - companies have to cut costs to survive. That often means reducing staff, outsourcing more work to contract manufacturers (CMOs), or squeezing more output out of fewer workers. Some experts warn this pressure could lead to quality issues, especially if experienced staff leave and are replaced by less-trained temps.Brand Drugs: Paying for Innovation - and Patents

Brand-name drugs cost 80% to 85% more than their generic equivalents - even though the actual pill is nearly identical. Why? Because the brand company paid $2.6 billion on average to develop it. That’s not a typo. It’s the real cost, according to the FDA. That includes 10 to 15 years of research, animal testing, clinical trials, legal battles, and regulatory paperwork. That cost has to be recovered before the patent expires. And that’s where labor comes in again. During development, brand-name companies hire teams of pharmacologists, data analysts, regulatory specialists, and trial coordinators. These aren’t factory workers. These are PhDs and MDs. Their salaries are high. Their hours are long. And they’re not making pills - they’re trying to prove a new molecule works safely in humans. That’s expensive labor. Once the drug is approved, production shifts to a more efficient model, but the overhead remains. Marketing, sales reps, patient support programs, and legal teams defending patents all add to the cost. Meanwhile, generic companies don’t have to pay any of that. They don’t need sales reps. They don’t run TV ads. They don’t fund clinical trials. Their labor force is leaner, focused on production, quality control, and logistics. That’s why, even though they make the same pill, their cost structure looks nothing like the brand’s.

The Real Trade-Off: Volume vs. Innovation

There’s a hidden tension in this system. Generic manufacturers rely on volume to keep labor costs low. But if prices drop too far, they can’t afford to hire skilled workers or invest in better equipment. That’s why the FDA has started warning that “lower cost of generic drugs may place pressure on companies to adopt strategies that lower the cost of manufacturing,” which could lead to shortages or quality problems. On the flip side, brand-name companies need high prices to fund the next breakthrough. Without that profit margin, new drugs wouldn’t get developed. But if generics keep driving prices down, even brand companies start cutting corners - delaying new projects, reducing R&D staff, or shifting focus to “me-too” drugs that offer little innovation. The system works because both sides play their role. Generics make the old drugs affordable. Brands create the new ones. But the labor cost gap between them is what makes the whole thing possible. Without that 60-70% lower labor burden on the generic side, most prescriptions would cost three to five times more.What This Means for You

As a patient, you benefit from this system every time you choose a generic. You’re not just saving money. You’re helping keep the entire healthcare system running. But you’re also part of a larger economic machine - one that depends on low labor costs abroad, high efficiency at home, and constant pressure to do more with less. The next time you see a $4 generic prescription, remember: it’s not just cheaper because it’s copied. It’s cheaper because thousands of workers - in India, China, and the U.S. - are making it faster, smarter, and under tighter constraints than ever before. And that’s not something you can see on the bottle. But it’s what makes the system work.Why are generic drugs cheaper if they’re the same as brand-name drugs?

Generic drugs are cheaper because their manufacturers don’t pay for research, clinical trials, or marketing. They copy an existing drug after the patent expires and focus on mass production. Labor costs are lower because processes are standardized, volumes are huge, and many ingredients are made overseas where wages are lower. Even though the pill is identical, the cost structure is completely different.

Do generic drug manufacturers pay less in labor costs than brand-name companies?

Yes. Brand-name drug production typically spends 30-40% of its total cost on labor during early development, because it involves scientists, regulators, and trial teams. Generic manufacturers spend only 15-25% on labor because they use proven processes, high-volume production, and fewer specialized roles. Their labor is focused on quality control and packaging, not invention.

Does making generics in India or China mean lower quality?

Not necessarily. The FDA inspects foreign manufacturing sites just like U.S. ones. Many generic drugs made overseas meet the same quality standards. But the lower costs come from lower wages, fewer environmental regulations, and government subsidies - not better technology. Quality is regulated, but the economic model is different.

Why do generic drug prices keep falling even when demand is high?

Because there are often 10-20 companies making the same generic drug. When more manufacturers enter the market, they compete on price. Even a small drop in price can make a big difference when you’re selling billions of pills. This forces companies to cut costs - including labor - to stay profitable.

Could cheaper generics lead to drug shortages?

Yes. When prices drop too low, some manufacturers can’t cover their costs and shut down production. Others cut staff or outsource to cheaper suppliers, which can lead to quality issues or delays. The FDA has warned that this pressure is a growing risk, especially for older drugs with low profit margins.

Author

Mike Clayton

As a pharmaceutical expert, I am passionate about researching and developing new medications to improve people's lives. With my extensive knowledge in the field, I enjoy writing articles and sharing insights on various diseases and their treatments. My goal is to educate the public on the importance of understanding the medications they take and how they can contribute to their overall well-being. I am constantly striving to stay up-to-date with the latest advancements in pharmaceuticals and share that knowledge with others. Through my writing, I hope to bridge the gap between science and the general public, making complex topics more accessible and easy to understand.